STORMTECH MC-4500

REQUIRED MATERIALS AND EQUIPMENT LIST

- Acceptable fill materials per the Acceptable Fill Materials Section

- ADS PLUS and non-woven geotextile fabrics

- StormTech solid end caps, pre-cored and pre-fabricated end caps

- StormTech chambers, manifolds and fittings

NOTE: MC-3500 chamber pallets are 77” x 90” (2.0 m x 2.3 m) and weigh about 2010 lbs. (912 kg) and MC-4500 pallets are 100” x 52” (2.5 m x 1.3 m) and weigh about 840 lbs. (381 kg). Unloading chambers requires 72” (1.8 m) (min.) forks and/or tie downs (straps, chains, etc).

IMPORTANT INFORMATION

A. This installation guide provides the minimum requirements for proper installation of chambers. Nonadherence to this guide may result in damage to chambers during installation. Replacement of damaged chambers during or after backfilling is costly and very time consuming. It is recommended that all installers are familiar with this guide, and that the contractor inspects the chambers for distortion, damage and joint integrity as work progresses.

B. Use of a dozer to push embedment stone between the rows of chambers may cause damage to chambers and is not an acceptable backfill method. Any chambers damaged by using the “dump and push” method are not covered under the StormTech standard warranty.

C. Care should be taken in the handling of chambers and end caps. End caps must be stored standing upright. Avoid dropping, prying or excessive force on chambers during removal from pallet and initial placement.

ADS “Terms and Conditions of Sale” are available on the ADS website, www.ads-pipe.com. Advanced Drainage Systems, the ADS logo, and the green stripe are registered trademarks of Advanced Drainage Systems, Inc. StormTech® and the Isolator® Row are registered trademarks of StormTech, Inc.

Call StormTech at 888.892.2694 for technical and product information or visit www.stormtech.com

REQUIREMENTS FOR SYSTEM INSTALLATION

Place non-woven geotextile over prepared soils and up excavation walls.

Place clean, crushed, angular stone foundation 9” (230 mm) min. Install underdrains if required. Compact to achieve a flat surface.

MANIFOLD, SCOUR FABRIC AND CHAMBER ASSEMBLY

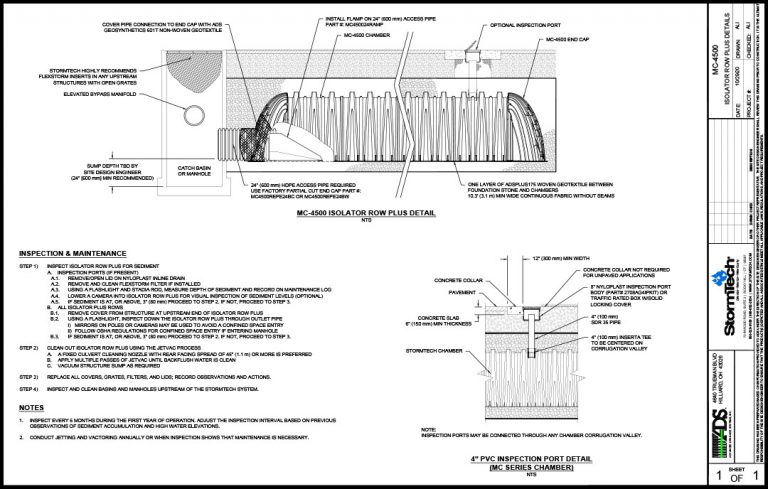

Install manifolds and lay out ADS PLUS fabric at inlet rows [min. 17 .5 ft (5.33 m)] at each inlet end cap. Place a continuous piece (no seams) along entire length of Isolator® PLUS Row(s).

Align the first chamber and end cap of each row with inlet pipes. Contractor may choose to postpone stone placement around end chambers and leave ends of rows open for easy inspection of chambers during the backfill process.

Insert inlet and outlet manifolds a minimum 12″ (300 mm) into chamber end caps. Manifold header should be a minimum 12″ (300 mm) from base of end cap.

Continue installing chambers by overlapping chamber end corrugations. Chamber joints are labeled “Lower Joint – Overlap Here” and “Build this direction – Upper Joint” Be sure that the chamber placement does not exceed the reach of the construction equipment used to place the stone. Maintain minimum 6″ (150 mm) spacing between MC-3500 rows and 9″ (230 mm) spacing between MC-4500 rows.

Place a continuous layer of ADS PLUS fabric between the foundation stone and the Isolator Row PLUS chambers, making sure the fabric lays flat and extends the entire width of the chamber feet.

When used on an Isolator Row PLUS, a 24″ FLAMP (flared end ramp) is attached to the inside of the inlet pipe with a provided threaded rod and bolt. The FLAMP then lays on top of the ADS PLUS fabric.

STORMTECH ISOLATOR ROW DETAIL

Figure 1: Isolator Row Detail

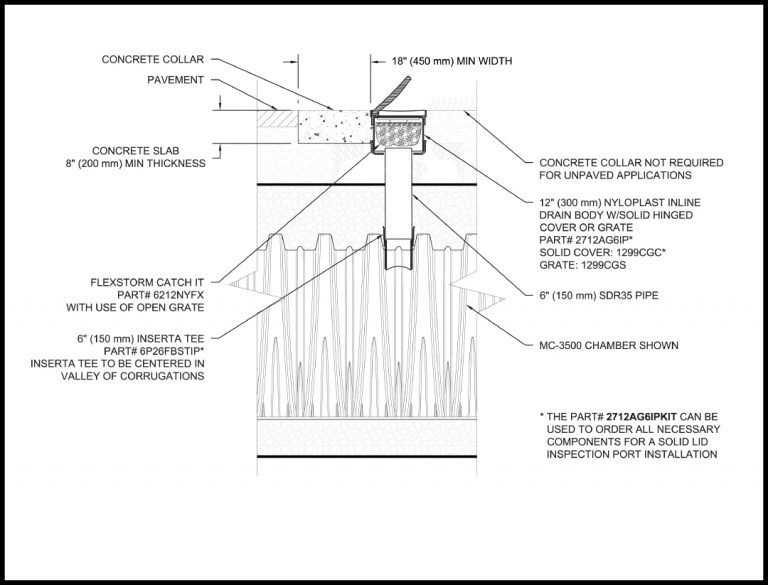

Figure 2: Inspection Port Detail

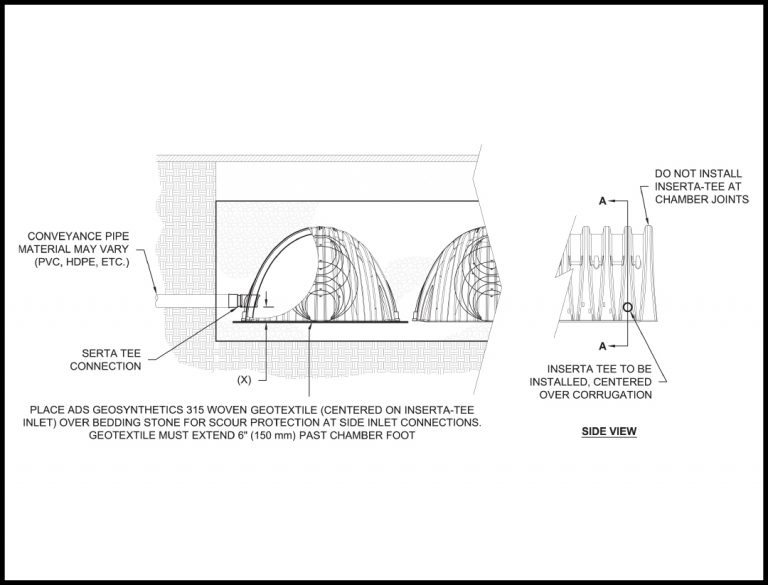

Figure 3: Inserta Tee Detail

INSERTA TEE FITTINGS AVAILABLE FOR SDR 26, SDR 35, SCH 40 IPS GASKETED & SOLVENT WELD, N-12, HP STORM, C-900 OR DUCTILE IRON

NOTE : PART NUMBERS WILL VARY BASED ON INLET PIPE MATERIALS. CONTACT STORMTECH FOR MORE INFORMATION.

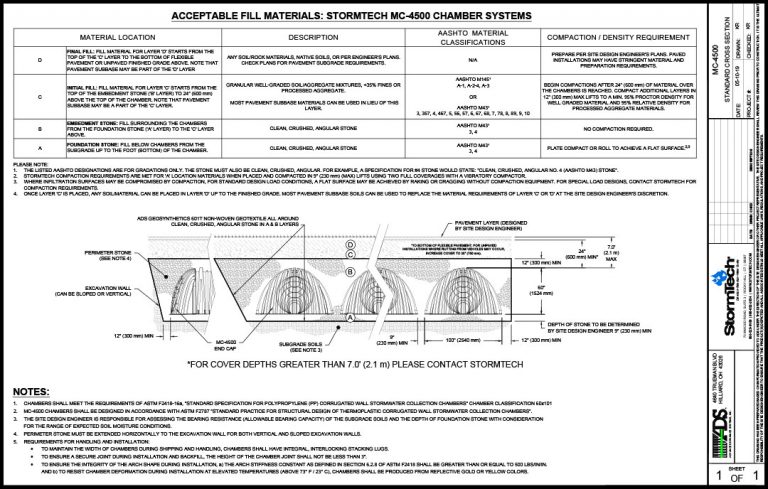

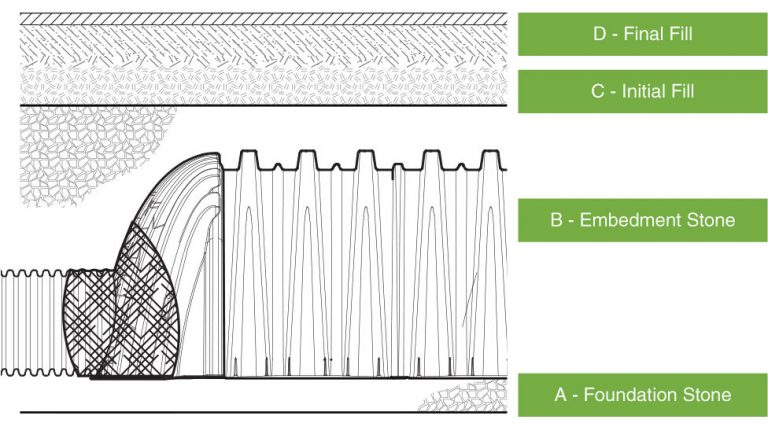

Figure 4: Fill Material Locations

INITIAL ANCHORING OF CHAMBERS - EMBEDMENT STONE

Initial embedment shall be spotted along the centerline of the chamber evenly anchoring the lower portion of the chamber. This is best accomplished with a stone conveyor or excavator reaching along the row.

No equipment shall be operated on the bed at this stage of the installation. Excavators must be located off the bed. Dump trucks shall not dump stone directly on to the bed. Dozers or loaders are not allowed on the bed at this time.

BACKFILL OF CHAMBERS – EMBEDMENT STONE

Backfill chambers evenly. Stone column height should never differ by more that 12″ (300 mm) between adjacent chamber rows or between chamber rows and perimeter.

Uneven Backfill – Incorrect

Even Backfill – Correct

Perimeter stone must be brought up evenly with chamber rows. Perimeter must be fully backfilled, with stone extended horizontally to the excavation wall.

Perimeter Not Backfilled – Incorrect

Perimeter Not Backfilled – Incorrect

BACKFILL OF CHAMBERS – EMBEDMENT STONE AND COVER STONE

Continue evenly backfilling between rows and around perimeter until embedment stone reaches tops of chambers and a minimum 12” (300 mm) of cover stone is in place. Perimeter stone must extend horizontally to the excavation wall for both straight or sloped sidewalls. The recommended backfill methods are with a stone conveyor outside of the bed or build as you go with an excavator inside the bed reaching along the rows. Backfilling while assembling chambers rows as shown in the picture will help to ensure that equipment reach is not exceeded.

Only after chambers have been backfilled to top of chamber and with a minimum 12” (300 mm) of cover stone on top of chambers can skid loaders and small LGP dozers be used to final grade cover stone and backfill material in accordance with ground pressure limits in the

Acceptiable Fill Materials Section.

Equipment must push material parallel to rows only. Never push perpendicular to rows. StormTech recommends the contractor inspect chamber rows before placing final backfill. Any chambers damaged by construction equipment shall be removed and replaced.

FINAL BACKFILL OF CHAMBERS – FILL MATERIAL

Install non-woven geotextile over stone. Geotextile must overlap 24” (600 mm) where edges meet. Compact at 24” (600 mm) of fill. Roller travel parallel with rows.

ACCEPTABLE FILL MATERIALS

D- Final Fill

Any soil/rock materials, native soils or per engineer’s plans. Check plans for pavement subgrade requirements.

Fill Material for layer ‘D’ starts from the top of the ‘C’ layer to the bottom of flexible pavement or unpaved finished grade above. Note that the pavement subbase may be part of the ‘D’ layer.

AASHTO M43 Designation*

N/A

Compaction/Density Requirement

Prepare per site design engineer’s plans. Paved installations may have stringent material and preparation requirements.

(Table 1D)

Wheel Loads

| Fill Depth Over Chambers in. [mm] | Max Axle Load For Trucks lbs [kN] | Max Wheel Load for Loaders lbs [kN] |

|---|---|---|

| 36” [900] Compacted | 32,000 [142] | 16,000 [71] |

Asphalt can be dumped into paver when compacted pavement subbase reaches 24” (600 mm) above top of chambers.

Track Loads

| Fill Depth Over Chambers in. [mm] | Track Width in. [mm] | Max Ground Pressure psf [kPa] |

|---|---|---|

| 36” [900] Compacted | 12” [305] | 3420 [164] |

| 18” [457] | 2350 [113] | |

| 24” [610] | 1850 [89] | |

| 30” [762] | 1510 [72] | |

| 36” [914] | 1310 [63] |

Small LGP track dozers & skid loaders allowed to grade cover stone with at least 12” (300 mm) stone under tracks at all times. Equipment must push parallel to rows at all times.

Roller Loads

| Fill Depth Over Chambers in. [mm] | Max Drum Weight or Dynamic Force lbs [kN] |

|---|---|

| 24” [600] Compacted | 20,000 [89] |

| 24” [600] Loose/Dumped | 16,000 [71] |

| 18” [450] | 5,000 [22] (static loads only)5 |

PLACEMENT METHODS/RESTRICTIONS

A variety of placement methods may be used. All construction loads must not exceed the maximum limits listed above.

(Table 3D)

ACCEPTABLE FILL MATERIALS

C- Initial Fill

Any soil/rock materials, native soils or per engineer’s plans. Check plans for pavement subgrade requirements.

Fill Material for layer ‘C’ starts from the top of the embedment stone (‘B’ layer) to 24” (600 mm) above the top of the chamber. Note that pavement subbase may be part of the ‘C’ layer.

AASHTO M43 Designation*

AASHTO M145 A-1, A-2-4, A-3 or AASHTO M431 3, 357, 4, 467, 5, 56, 57, 6, 67, 68, 7, 78, 8, 89, 9, 10

Compaction/Density Requirement

Begin compaction after min. 24” (600 mm) of material over the chambers is reached. Compact additional layers in 12” (300 mm) max. lifts to a min. 95% Proctor density for well-graded material and 95% relative density for processed aggregate materials.

(Table 1C)

MAXIMUM CONSTRUCTION LOADS6

Wheel Loads

| Fill Depth Over Chambers in. [mm] | Max Axle Load For Trucks lbs [kN] | Max Wheel Load for Loaders lbs [kN] |

|---|---|---|

| 24” [600] Compacted | 32,000 [142] | 16,000 [71] |

| 24” [600] Loose/Dumped | 24,000 [107] | 12,000 [53] |

| 18” [450] | 24,000 [107] | 12,000 [53] |

Asphalt can be dumped into paver when compacted pavement subbase reaches 24” (600 mm) above top of chambers.

Track Loads

| Fill Depth Over Chambers in. [mm] | Track Width in. [mm] | Max Ground Pressure psf [kPa] |

|---|---|---|

| 24” [600] Compacted | 12” [305] | 2480 [119] |

| 18” [457] | 1770 [85] | |

| 24” [610] | 1430 [68] | |

| 30” [762] | 1210 [58] | |

| 36” [914] | 1070 [51] | |

| 24” [600] Loose/Dumped | 12” [305] | 2245 [107] |

| 18” [457] | 1625 [78] | |

| 24” [610] | 1325 [63] | |

| 30” [762] | 1135 [54] | |

| 36” [914] | 1010 [48] | |

| 18” [450] | 12” [305] | 2010 [96] |

| 18” [457] | 1480 [71] | |

| 24” [610] | 1220 [58] | |

| 30” [762] | 1060 [51] |

Small LGP track dozers & skid loaders allowed to grade cover stone with at least 12” (300 mm) stone under tracks at all times. Equipment must push parallel to rows at all times.

Roller Loads

| Fill Depth Over Chambers in. [mm] | Max Drum Weight or Dynamic Force lbs [kN] |

|---|---|

| 24” [600] Compacted | 20,000 [89] |

| 24” [600] Loose/Dumped | 16,000 [71] |

| 18” [450] | 5,000 [22] (static loads only)5 |

PLACEMENT METHODS/RESTRICTIONS

Excavator positioned off bed recommended. Small excavator allowed over chambers. Small dozer allowed.

(Table 3C)

ACCEPTABLE FILL MATERIALS

B- Embedment Stone

Clean, crushed, angular stone

Fill the surrounding chambers from the foundation stone (‘A’ layer) to the ‘C’ layer above.

Minimum 12″ (300 mm) cover stone on top of chamber.

AASHTO M43 Designation*

AASHTO M43 – 3, 357, 4

Compaction/Density Requirement

No compaction required.

MAXIMUM CONSTRUCTION LOADS6

Wheel Loads

| Fill Depth Over Chambers in. [mm] | Max Axle Load For Trucks lbs [kN] | Max Wheel Load for Loaders lbs [kN] |

|---|---|---|

| 12” [300] | NOT ALLOWED | NOT ALLOWED |

| 6” [150] | NOT ALLOWED | NOT ALLOWED |

No wheel loads allowed. Material must be placed outside the limits of the chamber bed.

Track Loads

| Fill Depth Over Chambers in. [mm] | Track Width in. [mm] | Max Ground Pressure psf [kPa] |

|---|---|---|

| 12” [300] | 12” [305] | 1100 [53] |

| 18” [457] | 715 [34] | |

| 24” [610] | 660 [32] | |

| 30” [762] | 580 [28] | |

| 6” [150] | NOT ALLOWED | NOT ALLOWED |

No tracked equipment is allowed on chambers until a min. 12” (300 mm) cover stone is in place.

Roller Loads

| Fill Depth Over Chambers in. [mm] | Max Drum Weight or Dynamic Force lbs [kN] |

|---|---|

| 12” [300] | NOT ALLOWED |

| 6” [150] | NOT ALLOWED |

No rollers allowed.

PLACEMENT METHODS/RESTRICTIONS

No equipment allowed on bare chambers. Use excavator or stone conveyor positioned off bed or on foundation stone to evenly fill around all chambers to at least the top of chambers.

Minimum 12″ (300 mm) cover stone on top of chamber.

(Table 3B)

ACCEPTABLE FILL MATERIALS

A – Foundation Stone

Clean, crushed, angular stone

Fill below chambers from the subgrade up to the foot (bottom) of the chamber.

AASHTO M43 Designation*

AASHTO M43 – 3, 357, 4

Compaction/Density Requirement

Place and compact in 9” (230 mm) max lifts using two full coverages with a vibratory compactor.**, ***

(Table 1A)

PLACEMENT METHODS/RESTRICTIONS

No StormTech restrictions. Contractor responsible for any conditions or requirements by others relative to subgrade bearing capacity, dewatering

or protection of subgrade.

(Table 3A)

PLEASE NOTE:

*. The listed AASHTO designations are for gradations only. The stone must also be clean, crushed, angular. For example, a specification for #4 stone would state: “clean, crushed, angular no. 4 (AASHTO M43) stone”.

**. StormTech compaction requirements are met for ‘A’ location materials when placed and compacted in 9” (230 mm) (max) lifts using two full coverages with a vibratory compactor.

***. Where infiltration surfaces may be comprised by compaction, for standard installations and standard design load conditions, a flat surface may be achieved by raking or dragging without compaction equipment. For special load designs, contact StormTech for compaction requirements.

1. 36” (900 mm) of stabilized cover materials over the chambers is required for full dump truck travel and dumping.

2. During paving operations, dump truck axle loads on 24” (600mm) of cover may be necessary. Precautions should be taken to avoid rutting of the road base layer, to ensure that compaction requirements have been met, and that a minimum of 24” (600 mm) of cover exists over the chambers. Contact StormTech for additional guidance on allowable axle loads during paving.

3. Ground pressure for track dozers is the vehicle operating weight divided by total ground contact area for both tracks. Excavators will exert higher ground pressures based on loaded bucket weight and boom extension.

4. Mini-excavators (<8,000lbs/3,628 kg) can be used with at least 12” (300 mm) of stone over the chambers and are limited by the maximum ground pressures in Table 2 based on a full bucket at maximum boom extension.

5. StormTech does not require compaction of initial fill at 18” (450 mm) of cover. However, requirements by others for 6” (150 mm) lifts may necessitate the use of small compactors at 18” (450 mm) of cover.

6. Storage of materials such as construction materials, equipment, spoils, etc. should not be located over the StormTech system. The use of equipment over the StormTech system not covered in Table 2 (ex. soil mixing equipment, cranes, etc) is limited. Please contact StormTech for more information.

7. Allowable track loads based on vehicle travel only. Excavators shall not operate on chamber beds until the total backfill reaches 3 feet (900 mm) over the entire bed.